Within the framework of the Hanoi City-level science and technology task “Research on nitrogen and phosphorus recovery technology in pig farm wastewater using fluidized bed struvite granulation technique to produce organic fertilizer”, chaired by Dr. Le Van Giang, Central Institute of Natural Resources and Environment Studies, VNU, has brought about excellent results in animal husbandry.

Pig farm wastewater is a source of waste with a high risk of polluting the environment, especially surface water sources. However, from a circular economy perspective, pig wastewater is a valuable resource, providing N-P-K nutrients, which can partially replace natural deposits that are gradually depleted.

Pic 1. Laboratory-scale FBHC technology model for nitrogen and phosphorus recovery in pig wastewater.

The trend of the world in general and Vietnam in particular is a substantial shift from small-scale household-managed pig farming, located in residential areas, to concentrated pig farming on a larger farm scale (industrial or household), with a considerable amount of waste generated daily, causing severe environmental pollution, thus becoming an environmental hotspot causing public outrage.

To address the environmental pollution issue associated with pig farms, biogas technology has been widely adopted to treat pig waste. Biogas tanks can be built with bricks, precast composite or waterproof tarpaulin. Some farms use manure separators to recover solid waste before sending wastewater to the biogas tank.

However, the most significant limitation of biogas technology is that it can only process organic components through the anaerobic decomposition mechanism of microorganisms to recover CH4 gas for cooking, electricity generation or lighting purposes. N-P-K nutrients are left largely unprocessed, which is the primary cause of eutrophication and pollution in surface water, groundwater, and air.

Pig farm wastewater is a mixture containing three main components: solid waste, wastewater, and exhaust gases. On average, each pig produces about 20-25 litres of wastewater per day and about 0.5-3.0 kg of solid faecal waste per day, depending on the age, diet, and ration of the pig. Thus, wastewater accounts for the most significant proportion, including a mixture of urine, barn cleaning water, pig bathing water, spilt drinking water, and contains part or all of the pig faeces.

The composition of wastewater is diverse, including suspended solids, dissolved organic and inorganic substances, especially nitrogen, phosphorus, and potassium. Pig wastewater contains many microorganisms and pathogenic biological factors. The concentration of pollutants in pig wastewater depends on several factors, including the composition of faeces and urine, the amount of spilt or excess food, the amount of antibiotics used, the barn system, and the collection and treatment of wastewater.

According to the analysis results, pig wastewater contains very high concentrations of nutrients, including phosphorus, potassium, and nitrogen.

There are numerous pig farm wastewater treatment methods worldwide that extract and collect N-P-K compounds, including nitrification and biological denitrification, metal ion precipitation, adsorption, NH3 gas separation and precipitation, electrochemical conversion, ion exchange, and microbial electrolysis. However, the disadvantages of these methods are low efficiency, high energy consumption, economic infeasibility, and minimal practical application. Currently, fluidised bed crystallisation (FBC) technology for recovering Struvite (MgNH4PO4) in pig wastewater treatment is a relatively new technology, offering promising advantages such as high treatment efficiency, low investment costs, easy operation, and the potential for full industrial-scale development.

The FBC technology, featuring a fluidised bed reaction column, enables heterogeneous granulation by utilising seed particles such as SiO2 and Al2O3 to create an environment conducive to the adhesion and development of reactants. Consequently, the recovered Struvite product often has low purity, high humidity (low quality), and limited practical reuse. At the same time, another significant disadvantage of FBC technology is that it generates a large amount of waste sludge, which incurs considerable costs to treat and manage.

To thoroughly solve the environmental challenges of the Vietnamese pig farming industry nowadays, in recent years, the Vietnam National University-level Strong Research Group “Resource Recovery and Sustainable Energy Regeneration” of the Central Institute of Natural Resources and Environment Studies has focused on researching, developing and perfecting the fluidized bed homogeneous crystallization (Fluidized Bed Homogeneous Crystallization – FBHC) technology, to overcome the limitations and disadvantages of FBC technology. FBHC is considered an advanced technology, superior to FBC technology and conventional precipitation methods, thanks to the use of low-dose chemicals, high-purity Struvite (MgNH4PO4) crystals and low water content (below 5%), capable of completely converting sludge into solid form, while also being easy to operate with no need for building additional treatment tank systems, requiring little space to install the equipment system.

From the equipment modules designed in laboratory conditions on the 3rd floor of the HT1 Building of VNU Hanoi’s Hoa Lac campus, the Strong Research Group has now completed and mastered the FBHC technology with full application capability to the treatment of wastewater from concentrated pig farms to recover N-P-K for slow-release mineral fertilizer (Struvite) with high quality.

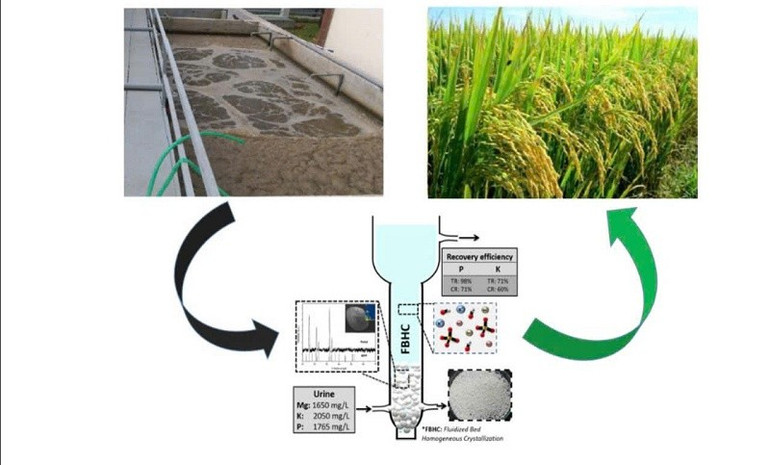

Within the framework of the Hanoi City-level science and technology task “Research on nitrogen and phosphorus recovery technology in pig farm wastewater using fluidized bed struvite granulation technique to produce organic fertilizer”, led by Dr. Le Van Giang, implemented from 2023-2025, the Strong Research Group has designed, manufactured, installed and operated an equipment system applying FBHC technology, with a capacity of 5 m3/day and night for a household pig farm in Son Tay Town with a scale of 300 pigs being raised. The trial operation of the treatment equipment system yielded positive results.

Pic 2: Overview diagram of FHBC technology to recover NPK in pig farming wastewater and reuse it as slow-release mineral fertilizer

Up to now, the Strong Research Group “Resource Recovery and Sustainable Energy Regeneration” at the Institute of Natural Resources and Environment has calculated the economic, technical, and environmental efficiency of FBHC technology and designed a large-capacity equipment system ready to be transferred to pig farms with scales ranging from thousands to tens of thousands of pigs. FBHC technology developed and perfected by the Strong Research Group has provided an advanced, modern and entirely feasible technological solution to comprehensively solve the problem of environmental pollution caused by wastewater from concentrated pig farms from household scale (several hundred pigs) to industrial scale (tens of thousands of pigs) in the direction of circular economy, contributing to promoting sustainable pig farming and enhancing the competitiveness of pork products in the context of Vietnam’s intense efforts to implement international commitments on combating climate change (Paris Agreement) and reducing greenhouse gas emissions (COP26).

This research result is one of the focused and key investment achievements of Hanoi National University in the direction of fostering strong Research Groups, investing in developing key laboratories to carry out the R&D mission, perfecting scientific and technological products ready to transfer to people and businesses, to contribute to the active, effective and early implementation of Resolution No. 5. This research result is one of the focused and key investment achievements of Hanoi National University in the direction of fostering strong Research Groups, investing in developing key laboratories to carry out the R&D mission, perfecting scientific and technological products ready to transfer to people and businesses, to contribute to the active, effective and early implementation of Resolution No. 57-NQ/TW dated December 22, 2024 of the Politburo on breakthroughs in science, technology development, innovation and national digital transformation into everyday life.

In addition, the Strong Research Group is researching the application of FBHC technology to treat many different types of industrial wastewater (electroplating industry, iron and steel production industry…) to recover valuable metals (Al, Ni, B, Fe, F, Zn, Cu) or wastewater containing inorganic acids such as phosphorous acid and boric acid.

Written by: Assoc.Prof., Dr. Luu The Anh

(Central Institute of Natural Resources and Environment Studies, Vietnam National University, Hanoi)